Microporous Membrane in Coalescing Oil from Water

Published: 8 May 2024

In many applications of microporous membrane processes, the pore size on the membrane surface determines the separation performance i.e. based on molecular sieving mechanism. In the case of oil-water emulsion, the separation by using the polymeric microporous membrane behaves differently and molecular sieving mechanism may not be applicable.

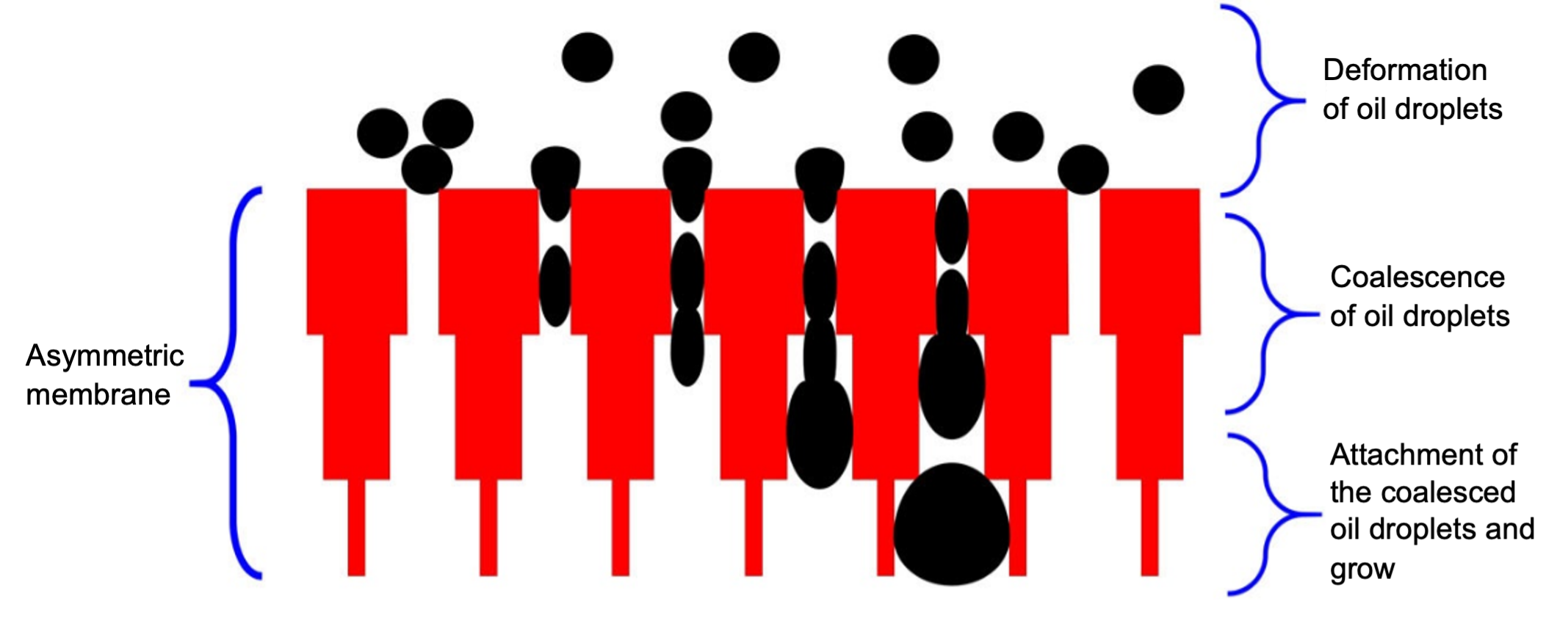

Figure 1. Asymmetric structures of (a) macrovoids, (b) long fingerlike, (c) short fingerlike and, (d) sponge-like of polyvinylidene fluoride membranes prepared by NIPS method

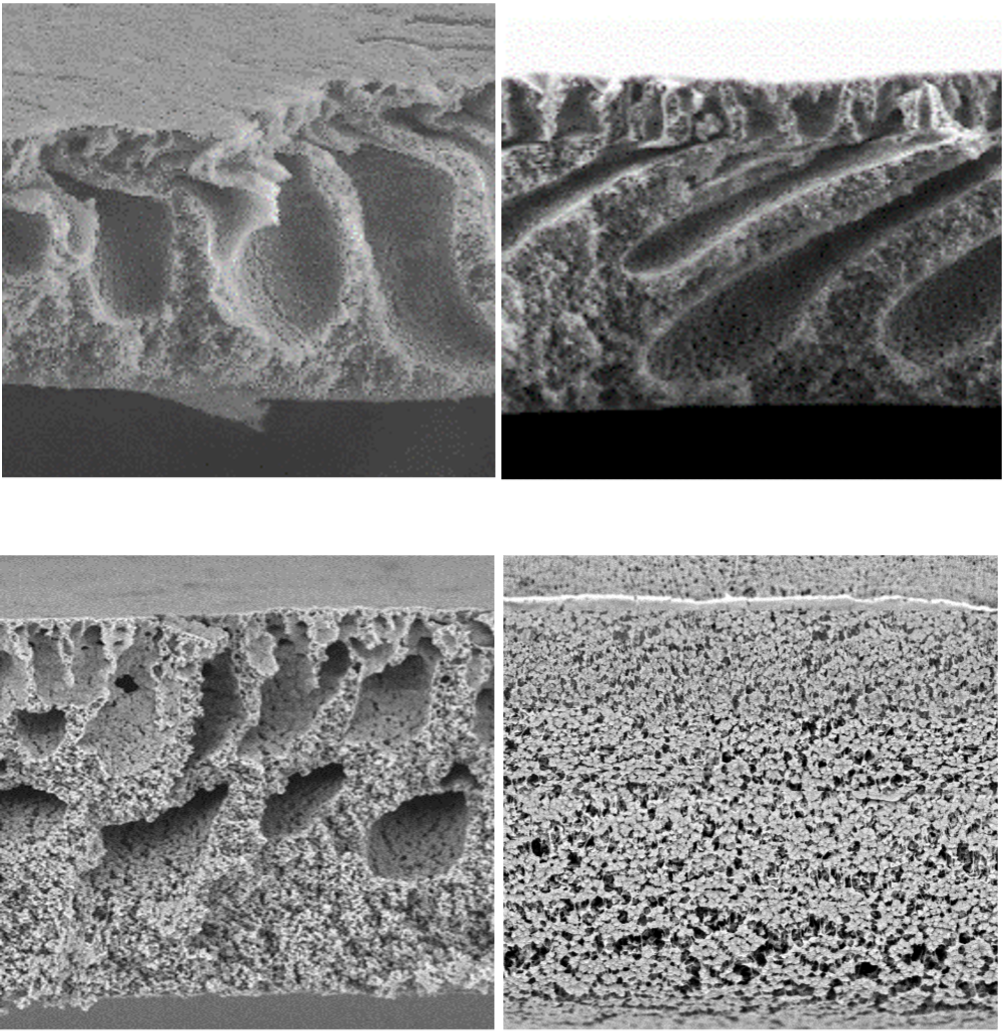

Figure 2. Oil droplet size distribution in permeates through polyvinylidene fluoride membranes at transmembrane pressure 2 bars.

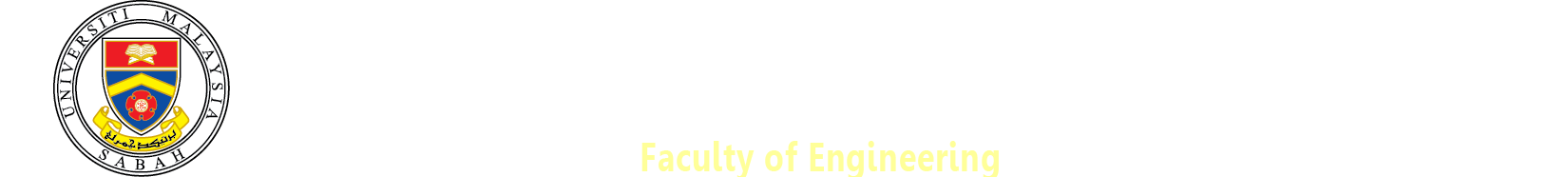

Oil droplets in water are instable and tend to coalesce to form larger droplets. Contrarily, smaller oil droplets are more stable and the leaning to merge with each other is low. In this research, the stabilized oil droplets are placed on the microporous membrane surface with narrow pores. The surfactant film of oil droplet is sheared off through deformation as the result of the friction at the pore wall. The oil droplets without surfactant films will collide and coalesce within the asymmetric membrane pore path as illustrated in the top figure. The smaller membrane surface pore size can enlarge the oil droplets from below 0.4 micron to approximately 5.6 micron.

Nonsolvent-induced phase separation (NIPS) is a versatile technique to tailor the asymmetric membranes. Water is a popular coagulant in making the microporous membrane with asymmetric structure. Membrane with fingerlike macrovoids and cavities-like structure is essentially formed via a rapid coagulation rate. The transition structure from macrovoids to long fingerlike, short fingerlike and sponge-like structures can be accomplished by adding additives to lower the rate of coagulation (Figure 1).

The pore size on the membrane surface changes correspondingly. With a proviso of membrane surface pore size is larger than the fine oil droplets, the tortuous structure of pore paths within asymmetric matrix membrane functions to deform the droplets. By testing with droplets below 0.2 micron in a feed oil/water emulsion, the tortuous asymmetric membrane can coalesce the droplets with at least 65% of droplets sized exceeding 1.0 micron in permeate (Figure 2).

Further reading:

https://doi.org/10.1080/00986445.2020.1761798

https://doi.org/10.1080/00986445.2022.2081563

Hypothetical coalescence of oil droplets in the asymmetric microporous membrane.